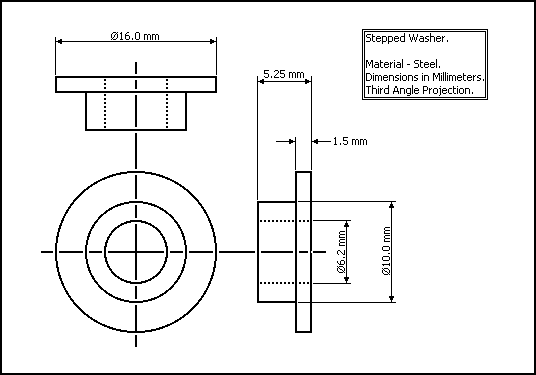

Homemade Rear Tail Bracket Stepped Washer.

![]()

Stepped Washer Diagram & Dimensions.The drawing is a png image!Right click and "Save Picture / Image As" if a copy is required.  |

Tools and materials.This item is very simple to make if you have the tools and materials available, ideally you need the following...1. Diameter 16mm or bigger steel bar or equivalent material about 100mm in length. 2. Number 3 Centre drill. 3. Diameter 6.2mm drill suitable for drilling steel. 4. Metal turning lathe. 5. Digital vernier calipers, vernier calipers or 0 - 25mm micrometer for measuring. 6. Can of black spray paint aerosol. Method. 1. Place bar in a 3 jaw chuck or collet with about 20mm protruding. 2. Turn to diameter 16.0mm for a length of 10mm or so. 3. Face the bar end, centre drill and drill a hole diameter 6.2mm, 10mm or so deep. 4. Turn the diameter 10mm, for a length of 3.75mm attaining a square corner, (a small radius in the corner no bigger than 0.5mm is acceptable). 5. Part off at a length of 5.25mm. 6. Remove burrs. 7. Coat with black spray paint to prevent rusting. |